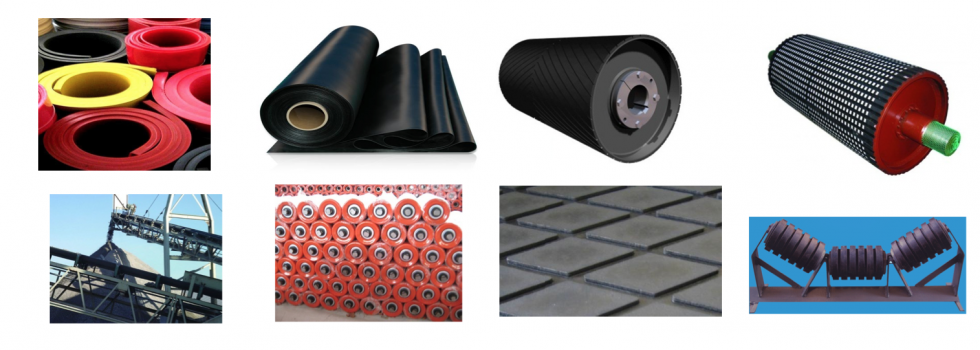

PolyStl™ Liners

PolyStl™ liners are suitable for AG Mills, SAG Mills, Primary Mills and Ball Mills with ball diameters 3 ½ inches and larger.

PolyStl™ liners are the composite of a Special Wear Resistant Steel and High Pressure Moulded Rubber. Similar liner designs have been used for many years in AG / SAG mills up to 32 feet in diameter.

PolyStl™ liners are usually installed with Rubber Plates. This reduces the overall weight of the liner assembly. As well, loads on shells, heads and bearings will also be reduced.

PolyStl™ liners lasts longer than steel liners in many applications, thereby reducing cost per ton of ore processed.

The noise level with a PolyStl™ lined mill is lower than that of a steel lined mill.

Combination Lining

Combination linings combine the advantages of steel lifters with moulded wear resistant rubber plates.

Combination liners have been used for many years in tough applications in up to 32′ AG Mills, SAG Mills, or primary ball mills using plus 3 ½ inch balls.

Advantages of Combination lining:

- less weight than all steel lining.

- reduced structural and bearing loads.

- lower operating costs.

- easier to replace.

- reduced noise.

Rubber Liners

Rubber Mill Liners are chosen for most Primary, Secondary and Tertiary Ball Mills. And in many cases rubber components are best suited for specific areas in AG and SAG mills.

Rubber Mill Liners are extensively used in FGD mills at Power Plants all over the world.

Polycorp has supplied complete rubber linings in some of the largest ball mills in North America at 24 feet in diameter.

We have supplied Rubber Liners for more than 400 mills worldwide.

Polycorp lifters are made of tough abrasion resistant rubber with decades of proven field use, guaranteeing their ability to withstand the relentless pounding of mill action. They are available in a selection of profile designs and heights to give unexcelled performance under various grinding mill conditions.

Polycorp’s rubber liners are designed and arranged so that the lifter bars can be easily replaced without affecting the shell plates, which can outlast lifter bars by at least two to one. Our lifter bars are engineered to be compatible with most shell and end liner plate designs.

Our rubber lifter bars will utilize your current bolt hole spacing. This eliminates the need to drill new attachment holes. All components are moulded to meet your specific mill and operating conditions.

THE ADVANTAGES OF POLYCORP RUBBER MILL LINERS

- LOWER COST

These are very cost effective as COST PER TON OF ORE GRIND IS LOWER. - LONGER LIFE

Rubber Mill liners have LONGER OPERATIONAL LIFE. - LESS MAINTENANCE

Rubber Mill Liners are engineered to resist abrasion, increasing the interval between maintenance intervals. - FASTER / SAFER

Rubber Components are lighter and easier to handle - REDUCED NOISE

Rubber Mill Liners REDUCE THE NOISE LEVEL to safer levels by absorbing impact against the shell - REDUCED WEIGHT

Rubber Liners are about 1/8 by weight of steel liners of same size - REDUCED INVENTORY

Rubber Mill Liners have a PREDICTABLE WEAR RATE so inventory planning is easy. - NO LEAKAGE

Rubber mill liners seal to the shell eliminating slurry leakage from the mill. - REDUCED POWER

Light weight of Rubber Mill reduces the current draw of the mill. - INCREASED BEARING / PINION LIFE

Reduced weights and leak proof fixing increase the normal life of the Pinion Gear and Bearings. - DEDICATED AFTER SALES SERVICE

We have fully trained Service team to assist you. - EASY TO MANAGE SPARES

Shorter lead times insure quick delivery of required spares.

Rubber Metal Pulp Lifters

Polycorp specializes in design and manufacture of both Radial and Curved Rubber Metal Pulp Lifters.

These are suitable for AG / SAG and Primary Mills. The Rubber Metal Pulp lifters are manufactured with specially hand laid rubber on the metal structure.

We routinely supply Rubber Metal Pulp Lifters for up to 38 ft diameter SAG mills, all over the world.

Our Rubber covered Metal Pulp Lifters can be easily retro-fitted with existing drill holes in the discharge head.

Our Pulp Lifters are specially designed to improve mill throughput and to avoid over grinding.

Rubber Metal Pulp Lifters are designed and manufactured with special wear resistant rubber for longer operating life and can also be designed with replaceable wear pads at maximum wear zones.

To ensure fit at the site, as part of our quality checks, Pulp Lifters are assembled on the plant floor using wooden mill head mock-ups. This ensures that the holes line up and avoids any surprise during installation.

Rubber Grates

Polycorp specializes in the design and manufacture of High Pressure Moulded Wear Resistant Rubber Grates.

These grates are manufactured with moulded rubber on a steel frame and chord reinforcement to provide strength and flexibility to resist pressure and localized impact of the grinding charge.

The rubber grates have tapered slots to minimize the plugging with near size particles.

Rubber grates are extensively used in AG / SAG & Primary ball mills. Polycorp regularly supplies rubber grates for mills up to 28 ft in diameter.

Advantages of Rubber Grates:

- Efficient slurry flow through the grates due to their flexibility.

- Minimised plugging by near size particles.

- Lighter than steel grates.

- Easy to install and safe to work with.

Discharge Systems

Polycorp specializes in the design and manufacture of Rubber Pulp Discharge Systems.

These systems are suitable for AG / SAG and primary ball mills. The Rubber Dischargers are manufactured with rubber hand-laid on a metal structure. Rubber Dischargers are designed and manufactured with wear resistant rubber for longer operating life and can also be designed with replaceable wear pads at maximum wear zones.

We are regularly supplying Rubber Dischargers for up to 38 ft diameter SAG mills worldwide.

Polycorp’s Rubber Dischargers can be easily retro-fitted to replace steel dischargers with existing drilled holes in the discharge head.

Our Rubber Dischargers are specially designed to improve mill throughput and to avoid back flow of slurry into the mill.

Before shipping the discharge end parts are assembled on a wooden mill head mock-up. This confirms hole alignments and serves to avoid any clearance and fit issues that may arise during installation.